Framing your tiny house is a really exciting time in your building process. When you tip that wall up for the first time the change is dramatic, the next wall goes up, then the rest and before you know it your home has a form. It’s an inspiring time in building your home, so here are some of the details on how to frame a tiny house.

Framing your tiny house is an important step because it’s the bones of your home on wheels. Don’t rush through this and make sure your walls are all straight, square and plumb before starting. Before you even start building you first wall, make sure your base is level, taking your time to level the trailer will go a long way to making sure your walls will be straight.

Marking Your Top Plate & Bottom Plate:

In this video, I get into how to lay out all my studs on the top and bottom plate. It’s important to do this planning to make sure your walls are straight and well laid out.

Building Your Tiny House Wall:

Once we’ve cut our studs to the right length and measured out all locations on your top and bottom plates, it’s time to start actually framing up the wall. We use ring shank nails and some screws to make this happen, check out this video for the details on how to build a wall for a tiny house:

Raising Your Tiny House Walls:

When you frame your tiny house, I find it best to lay the wall down on the trailer and use the flat bed of the floor to keep everything straight while you frame. From there you’ll need to raise the walls up onto the edge of the trailer and then lift it up and drop it on top of your anchor bolts. I had help from my father and brother to lift the walls into their place, with three people it was easy and went up fast!

Framing Over Your Fender

The fender of your trailer is a tricky spot because it’s a large span and can be a major area where water and bugs can get in. Below you can see how I did it on my tiny house. If I were to do it all over again, I’d make that board spanning over the wheel well a header. Framing it with two 2×4’s with a 1/2 inch piece of plywood sandwiched between them. You want to leave an air gap so that water can get out if it does work its way in.

Roof Framing For A Tiny House:

Framing the roof of my tiny house was the hardest part of the whole build in my mind. Being up high plus compound angles make it complicated. There is a fair bit of math involved and even pros have to take a second to think about it when you get to framing any complex dormers or bump-outs. The big trick here is taking your time and build a template for your roof rafters.

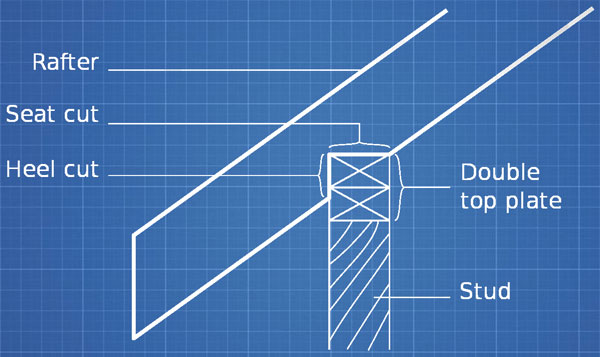

Cutting your rafters requires you to make “birds mouths” which are notches that will rest on top of the wall’s top plate. This is a complicated cut because you need to get the angles, position, and size of the cut perfect. Use a speed square (which you should own at least one!) to make these cuts.

Advanced Framing For Tiny Houses:

This is a technique that uses materials more efficiently and reduces weight, while still providing reasonable structure. Instead of your normal 16 inches on center, you’ll frame your walls 24 inches on center.

Advanced Framing Vs Traditional Framing:

ADVANCED FRAMING

- Studs are placed 24” on center

- 2×6 studs used

- Header hangers

- Headers are insulated

- Single stud for rough opening

- No cripple studs for windows

- Corners have just two studs

- Single top plate

TRADITIONAL FRAMING

- Studs are placed 16” on center

- 2×4 studs used

- Create headers with two boards

- Headers um-insulated

- Double up at windows

- Cripple board under the window

- Corners have four studs

- Double top plate

Framing Your Loft In A Tiny House

When it comes to the loft you want to make sure it’s sturdy, getting your loft framing is critical for a few reasons. First, you want to make sure it can support you, a mattress and anything else that might be kept in the loft area of your tiny house. The loft rafters also act like collar ties in some ways, preventing the roof from pushing out and collapsing in on itself.

The below video is about framing the roof, but you can see how I did my loft framing with 4×4 fir beams.

Tiny House Sub Floor Framing

The subfloor is the base of your framing, which will eventually sit right underneath your actual finished floors, but until you trim out your house it will be kept a raw floor. You want to frame your floor like you would a wall, doing 16 inches on center, but instead of sheathing, you want to use tongue and groove subfloor decking. Make sure that you glue and screw your subfloor decking to each stud to prevent squeaks later on.

A detailed guide on how to build your own tiny house using any set of plans or your own design. Learn what tools you’ll need, make the right choice with critical decisions, and understand key building techniques.

Wall Framing For A Tiny House FAQ

Can I frame my tiny house with aluminum framing?

Absolutely! Steel or aluminum framing are all viable options if you’ve done the engineering right. Metal framing is very strong but can flex and twist a bit more than wood would, especially if done incorrectly. Your go-to source for this type of framing is a company called Volstruckt, which does on-demand steel frames for tiny houses.

What about 2×2 wall framing for a tiny house?

For interior, non-load bearing walls you can absolutely go with 2×2 walls if you’re not running any electrical through it. It may get caught by an inspector for a code violation, so check your local building codes. Outside of interior and non-load bearing, you need to use at least 2×4 studs for your walls.

How Thick are tiny house walls?

Tiny House walls are about 4.75 inches thick. This includes your interior cladding (1/4″ thick), your wall framing filled with insulation (3.5″ thick), your sheathing (1/2″ thick), and your outer siding (typically 1/2″ +/- depending on your siding).

How Much Does Framing A Tiny House Cost?

A typical tiny house that’s 8 feet wide by 20 feet long will cost $300-$800 to frame. That is for only studs and fasteners. Sheathing will add around $800-$1,000 to that. Windows can run anywhere from $60 each to several hundred. Doors typically go from $300-$2,000.

What about house wrap?

My best advice is to look around your city and see what other builders are doing when it comes to house wraps and vapor barriers. These things are very climate specific, so tap into that local knowledge. I’m a huge fan of skipping the house wrap and using zip panels by Huber instead: they’re cheaper, more durable and don’t blow off in the wind.

My walls aren’t straight or square, how do I fix it?

First know that there is no wall that is 100% square, straight and plumb. We want to get as close as possible. First, make sure your trailer is actually level, just because it was a few days ago, doesn’t mean it still is. From there get a 6-foot level and look at your corners and how the stand. Then take a large carpenters square or laser level and check how square the wall are to themselves. Finally, fix them with ratchet straps, figure out which way you need to pull and use the straps to pull the wall into square.

You can practically live in it now! A bit of duct tape and some plastic……

I do not know how I missed your blog, I religiously check all the other tinyhouser’s every morning. Yours is added to the list 🙂

Con mucho gusto

Hi Ryan.

Wow! It looks great.

As the guy who came up with this “wall-over-well” design, I know a couple of it’s potential shortcomings. Fortunately, I also know how to more-or-less compensate for them before you go any further.

1) A shim should be placed in the gap between the wheel-well and wall framing beneath each vertical framing member (stud). So long as you do this and your wheel wells are structural (and it looks like yours clearly are), then this will make the wall structural as well.

2) Fill that entire gap with expanding spray-foam. This will act as insulation, and (more importantly) as a waterproof membrane. A more flexible membrane might be needed if you plan on traveling a lot on bumpy roads, so that it doesn’t crack on the road. I think the only post-occupancy complaints we ever received while I was at Tumbleweed pertained to wet walls around the wheel-wells (less lyrical than it sounds).

3) It looks like you have enough room between the innermost surface of your wheel-wells and the inside surface of your wall framing to fit a little insulation, and I think that will probably be just fine, considering that you see very little cold weather out in your neck of the woods. In any case, you should have room for enough insulation to keep that area above the dew-point. In my original designs for Tumbleweed, I believe I recommended making the whole house narrower to accommodate for colder climates and narrower trailers. In retrospect, I think building a little insulated box around that area would be a lot easier than re-configuring the whole design. The water-damage reported to Tumbleweed is probably as much the result of condensation from too little insulation as water infiltration due to an insufficient membrane situation (again, not nearly as lyrical as it would seem).

I think these original wall-over-well designs are still viable if you do them right, Ryan. And, so far, your right on track.

Jay

Yeah….about the duct tape….you had better do what Jay says instead 🙂

Just curious why you chose a trailer with wheel wells/fenders. I’m planning to use the 8’6″ x 16′ flatbed with the wheels under the bed. Seems a whole lot easier, or am I missing something? Probably lose a foot of height?

The trailer I used since it has the fenders, my deck height is 22 inches. Compare that to the trailers with the whole wheel under the trailer, it would have a deck height of 35″. That’s over a foot difference, if you can only go 13.5 feet tall because of DOT regulations then your loft is going to be tiny. My loft with this trailer will be just shy of four feet. Once you add a mattress you’ll have even less, so if you do the over the wheel setup then you’re looking at getting close to 3.5 feet for your loft, minus your thickness of the mattress. That’s going to get tight.

You could just design a house with the bed on the bottom floor I suppose.

Well you just sold me on the trailer your using!

I have a few questions, if you don’t mind.

1) Are you working from a set of public plans, working from a set of plans you made yourself, or winging it? I don’t think I’ve ever seen a plan that has a doorway over the tongue. At least, it looks like a doorway, except that it has extra supports / fire breaks.

2) Why add a wood floor frame above the trailer frame? Wouldn’t you get an extra 3.5″ of height by insulating and enclosing the frame from underneath (similar to the belly pans used by Airstream trailers)?

3) Did you purchase your windows and doors before you started framing the walls? If so, did you get them second hand or buy new, and why?

4) If you’re going to hurricane strap anyway, why not used 16d framing nails instead of screws? I’d think it would be just as structurally sound while being much faster, easier, and cheaper to frame.

Thanks in advance. At the very least, this should give you some blog post fodder. 🙂

1. The plans I am using are professionally designed and engineered. I think you are looking at the back of the trailer when your refer to what looks like a door over the tongue. That’s actually a window, you can see the sill and jack stud is there. I don’t have a photo of the door up there right now, but it’s at the other end, the one opposite of the tongue.

2. That is an interesting idea, I would think it would be quite cumbersome to install unless you ere able to flip the trailer over. The other consideration you would have to make is how much room you would need to allow for the leaf springs and axles to flex. Then you would need to protect it from road debris that will get kicked up, but I kind of like the idea. What if you were able to do both, you could have an R-40 floor which would be amazing!

3. Purchased new, see post here: https://www.thetinylife.com/ordering-windows/

4.I used both screws and ring shank nails in everything. I just screwed it together at first to be sure that I did everything correctly, once I verified all the measurements and that it was square, the whole thing was nailed. You also have to consider that the house needs to withstand the forces that it will see on the road, this is much higher than most traditional houses will ever see. Where I live code states a house needs to be able to withstand 90 mph, this house is engineered for 150 mph etc.

Thanks for your response. My confusion over your front window (the one over the trailer tongue) comes from the fact that the sill doesn’t have any jack studs supporting it. Even though your windows and wall are small, it seems to me that your sill should still be supported. The jack stud that you have holding up the header could have been sectioned so that the sill intersected it. I’ve seen plenty of windows that use an unsupported sill, but it would have used the same amount of wood to support it and would have made for a stronger structure. Just my $0.02.

I was thinking the same thing.

Some interesting framing there, looking at the tongue end your studs seem all over the place with no consistent “on-center” framing pattern unless its skewed by the picture.

I’ve always framed with sills and headers supported from beneath by jack studs so the load isn’t taken by the nails but by the stud beneath it.

I’ve never seen windows inserted almost a component section the way they are here, will be curious to see how much fun sheeting it is.

Thanks for showing photos as I didn’t want to sit through the videos. I love tiny homes but not so much the construction side of the story. I’ll look forward to your updates on this tiny house.

Is it possible to have the wheel wells constructed with square corners vice the standard rounded/tapered shape?

I realize this may increase the cost of the trailer. However, the ease with which to frame and, more importantly, achieve a water tight seal around a square wheel well would be a good investment in my books for both simplicity and peace of mind.

Cheers

DS

Yes it certainly could. With the tapered wells you have less flat space for water to sit on and potentially enter the house than a square well would have. A tapered well might mean you have less of a span to bridge of the well. In the end you are going to be using silicone regardless so I am not sure its really worth the trouble. It would be easier to cut the sheathing and the siding for a square wheel well for sure. I see pros and cons, but nothing significant for one way or the other. I say go for it!

Do you have pictures/video of the hurricane strapping? If you do, would you mind posting them? I want my house to be able to handle just about any situation too. Thanks.

Great photos and video Ryan. Great to see behind the scenes like this.

I’ve got a similar trailer and currently I’m tossing up my floor options – I’m extending the width beyond the trailer guards as my internal width is just 1570mm (sorry this is METRIC, we don’t use all this feet imperial stuff this side of the world) but I’m not really sure why I’d need a subfloor if I can weld more steel to give me the 1800+mm I desire (wheel guards exterior measure is 1770), and use ply for the flooring?

I’m taking the floor off mine came with (its too heavy, thick, and UNEVEN) mainly to rust proof the chassis properly and am thinking I could just go straight to a 12-19mm structural ply sheet floor, the house I’m building is gonna be way under a tonne (that’s about 2000lb I believe?).

Oh and my last issue is framing size. I understand “everyone” uses 2×4′ but what about ceiling framing? It’s about 2/3 this, would help me keep the trailer lighter and have a bit more space inside – okay not too much room saved there but still. Price is also a factor for me, so I am considering it – and have no building experience to think, hey this won’t work because of … I’m using tin roofing (again, light, cheap) and the only real load to the walls will be a loft bed, which is actually using the framing as supports (juts out a little like the gnomadik.com trailer, with structural supports also) and two (massive) windows. Any advice from anyone..? Before I dig myself a nice little… ..pond

I’m a little late to the party here, but if you wanna use your trailer deck as the floor for the house; use an axle-less suspension system. It will give you the room for welding on 15 gauge or high sheet metal to the bottom of the trailer. Then add the axle-less suspension system, your floor’s insulation and the decking. With no axles you don’t have to worry about axles or the leaf springs moving up and hitting the bottom of the trailer.

You don’t need to frame the floor!, it’s a waste of material and it makes no practical sense, not only that but it adds extra height. Fit 1.0mm aluminium sheet to the underside of the crossmembers, place your insulation in the crossmember cavities, and, lay your ply floor directly to the top of the trailer chassis/crossmembers. Whoever it was that came up with framing a floor should be horsewhipped, those that continue to do it should be cat o nine tailed… and anyone defending the practice wouldn’t have half a brain inside their head!!!

Don’t they frame a floor in order to have a warm floor in freezing weather. Otherwise, your feet would feel the extreme cold wherever the metal frame touch the plywood floor base. ????

Barry, as someone who is seriously material conscious, I also cringe when I read about idiots saying “I got my sub floor in” and al it is is wood and insulation, BIG WASTE OF MONEY and brain cells. I’m thinking of doing a tiny on an 18’ flatbed and the floor is in beautiful shape. I would think all that would have to happen is to seal the joints and poly it. No need to throw more weight and wood on top of it. It’s just me. My current tinywanderer came stock with 3/4 decking and I never added a thing to it. I put linoleum down and 1” Carpet in some spots. Sure it got cold sometimes , but I’m not a pussy, and I don’t sleep on the floor! Anyway to each their own but this is a lot of wasted wood!

It’s going to be ending of mine day, except before finish I am reading

this great post to increase my knowledge.

Can you frame your walls with steel studs and the roof as well . If so where would I find out how to frame it out in steel studs.

Can you make a tiny house self contained, like an RV?

what type of wood is best for framing