Figuring out how to level a tiny house was an important step in my own journey to tiny living. I had to consider whether to set my tiny home on blocks and which supports would work best. I learned a few things along the way and found a secure, solid, and level solution.

Read more →Posts Tagged DIY

Fencing is a vital fixture on any successful homestead. Building a homestead fence on your own can seem like a huge task, but when you break it down, anyone can put up a simple, sturdy wood or wire homestead fence.

Read more →Imagine being able to house your crops in a sunken greenhouse that self insulates and not having to worry about harsh winters or dry summers ruining your garden.

Read more →Making the decision to live in a tiny house is only the beginning of your journey! Once you decide to adopt the tiny life, you’ll need to figure out whether you want to build or buy your tiny home.

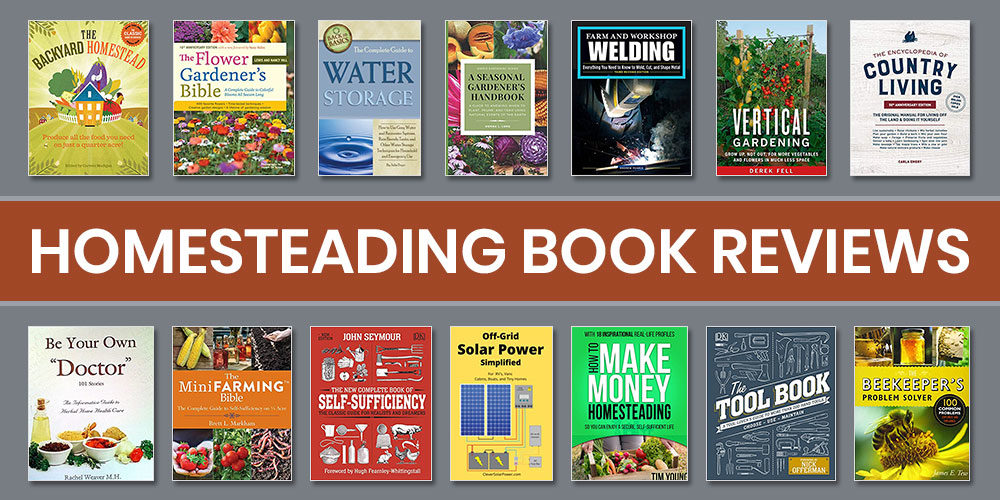

Read more →The practice of homesteading can find its way into one’s life in many different ways. For some, being a homesteader looks like producing your own food, making your own clothes, managing a small hobby farm, or generating your own power.

Read more →