NAVIGATION

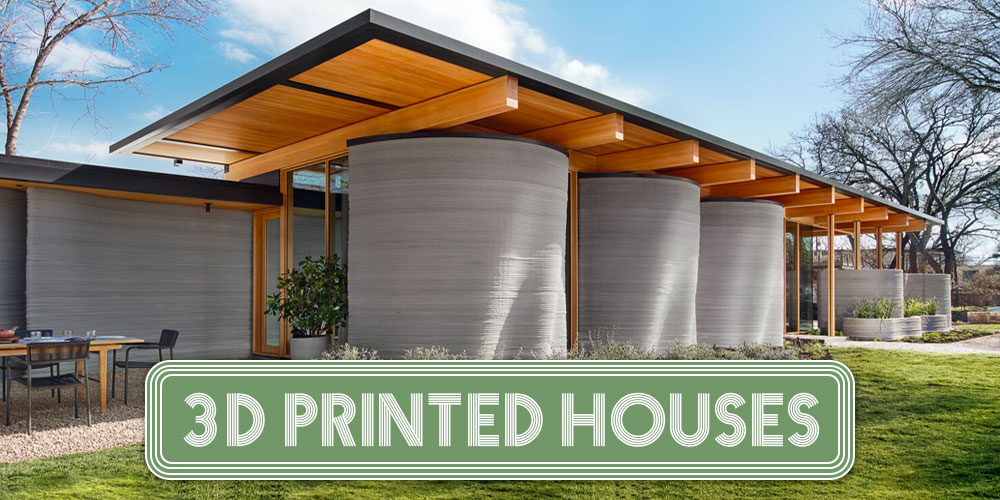

While the idea of 3D printing housing may have seemed far-fetched not that long ago, they are quickly becoming easier to build in our increasingly tech-dependent world. Building a 3D printed tiny house can be more cost effective, time efficient, and just as structurally durable as a traditional home.

Hi, I’m Ryan

As a guy with a natural fascination for both building houses and technology, the idea of 3D printing a house is right up my alley. Checking out examples of 3D printed tiny houses gets me excited about my own future as a tiny house builder.

What Are 3D Printed Tiny Houses?

3D printed tiny houses are fully livable homes that are built layer by layer with industrial-grade, 3D printing technology. A 3D printed house is created with a cone shaped printer that follows the builder and designer’s instructional code. The build and design team sets the concrete thickness, wall dimensions, and printing pace through their computer.

Back when I first heard the concept of 3D printing an entire house, I had no idea that industrial-grade printers were able to calculate and spit out the materials to build a home. While 3D printers focus primarily on the walls and foundation of the home, it’s impressive to understand the work they do and how far technology has come.

Back when I first heard the concept of 3D printing an entire house, I had no idea that industrial-grade printers were able to calculate and spit out the materials to build a home. While 3D printers focus primarily on the walls and foundation of the home, it’s impressive to understand the work they do and how far technology has come.

After the instructional code is set, the 3D printer will then do exactly what it’s told and manufacture the foundation and outer walls of the house, layer by layer. The process looks kind of like a giant tube of toothpaste squeezing out line after line of wet concrete.

FAQ: Common Questions About 3D Printing A Tiny House

Not only was I curious about what a 3D printed tiny house was, I also had tons of questions about the way they’re manufactured, how much they cost, whether or not they’re legal, and more. So I’ve done some digging.

What Are 3D Printed Houses Made Of?

3D printed houses can be made out of a variety of materials including concrete, recycled plastic, rice waste, mud, sand, or even soil. Some variation of concrete is most common, but industrial printers can work with lots of different materials.

How Long Does Printing A 3D House Take?

In 2023, industrial-sized 3D printers are able to print an entire home in less than 24 hours for a tiny house at 225 square feet or less. Larger homes will take significantly more time. Additionally, this estimate does exclude any pauses taken for second round error corrections, setup time needed for the framework and scaffolding, or any additional installations completed after the home is printed.

Where Can You Buy A 3D Concrete Printer?

In order to make a 3D printed house happen, you’ll need to hire a specialist who knows how to use an industrial-grade 3D printer. It’s not yet possible to build a 3D printed house on your own. Only specialists are able to do this right now, but the ability to DIY these is likely to be coming around the corner in the future.

3D printing specialists, as well as companies that make 3D printers like this, can be hard to come by and therefore tend to cost a pretty penny. The 3D printing method will likely become more accessible to the common public in the near future, but for now, you’ll need to confer with the experts.

3D Concrete Printers And Builders (To Buy Or Hire)

Are 3D Printed Homes Legal In The United States?

In the United States, 3D printed houses must follow all of the same legal building codes, rules, and regulations as a traditionally built house at this time. Legislation hasn’t quite caught up with the 3D printing housing trend yet.

In June 2022, the National Association of Home Builders brought forward the idea of developing a separate building code category for 3D printed housing regulations, but this is still in the works. While it’s highly likely that houses like this may develop their own laws in the future, they’re under general laws for now.

How Much Does It Cost To Build A 3D Printed House?

3D printed houses can cost anywhere from $10,000 to $400,000 depending on the house’s location, size, amenities, and materials used. The cost of a 3D printed tiny house also depends on whether or not you factor the cost of the industrial printer or specialized builder into the overall cost.

Pros And Cons Of 3D Printing Housing

While 3D printed houses are certainly the face of the future, the process is still up and coming. There are many advantages to using a 3D printer to build a tiny house, but also many disadvantages.

3D Printing Housing Pros and Cons

Pros

- Reduced risk of construction errors

- Safer than traditional construction methods

- Less construction waste and unused materials

- One of the fastest construction methods to date

- Cost of building materials and labor is less

- Less effort for the builder

Cons

- Not yet an exact science

- Few available designers and builders

- Only builds the outer walls, not the whole house

- Building code complications

- 3D concrete printers are expensive

- Requires a specialist to complete the build

3D Printed Tiny House Design Inspiration

The interior and exterior design of a 3D printed tiny house looks very similar to a traditional home. There are many ways to decorate and accentuate a 3D printed home to gives a nod to its unique origins.

3D Printed Home Interior Examples

Many rooms inside 3D printed tiny homes are open concept. Designers use embellishments likes shelves and room dividers to separate these rooms.

3D Printed Tiny House Living Room Inspiration

Personally, I like the living room designs that are open concept and include a kitchen nook within the living room space. I think living room interiors, even in 3D printed homes, look best with cozy, softer décor to truly make it feel like a space where you can kick back and relax.

3D Printed Tiny House Kitchen Inspiration

All of my favorite kitchen spaces have lots of natural light. I also enjoy when kitchens feature more earthy décor like plants or wood and stone accents.

3D Printed Tiny House Bedroom Inspiration

I also like bedroom designs with natural, minimalistic aesthetics. This could look like a wicker side table, bohemian rug, or simplistic yet personal wall hangings.

3D Printed Tiny House Office Inspiration

To me, the best office design inspiration in a 3D home is one filled with simple décor like plants and lots of natural light. I like to make sure any office space I have is filled with inspiring décor as well to keep me motivated in my work.

3D Printed Home Exterior Examples

Designing the exterior of your 3D printed tiny house comes with lots of creative freedom. I love 3D printed homes with intricate landscaping and an aesthetically pleasing use of materials. Someday if I build my own 3D printed home, I plan to design the exterior using an abundance of neutral colors like cream, gray, and beige.

3D Printed Tiny House With Wrapped Porch

Many 3D house exteriors have a porch or balcony that wraps all the way around the home. Some of the homes even have rooftop balconies or decks.

Two Connected 3D Printed Tiny Houses

Some designers use two separate frameworks to build two connected 3D printed homes. The houses are often connected with a porch, a sunroom, a garden, an atrium, or another central room.

3D Printed Tiny House With Textured Exterior

Some of the more unique 3D printed house exteriors that I’ve seen are ones with textured concrete walls. In order to create this, the designer would have had to pre-program the printer to create these textured waves.

3D Printed Tiny House Floorplans

When it comes to designing the floorplan or blueprint of your 3D home, a designer will create the basic blueprint, and that blueprint will be sent to the modeling software so the printer is prepared to do its work. There are many ways you can design a 3D printed home to fit your lifestyle needs.

The 3D printed tiny house floorplans can include all kinds of features to truly turn your house into a home. The blueprints might include one or multiple bedrooms, a laundry room or nook, a quaint kitchen, a corner office, or extensive space for windows. Designing a floorplan is your chance to dream big!

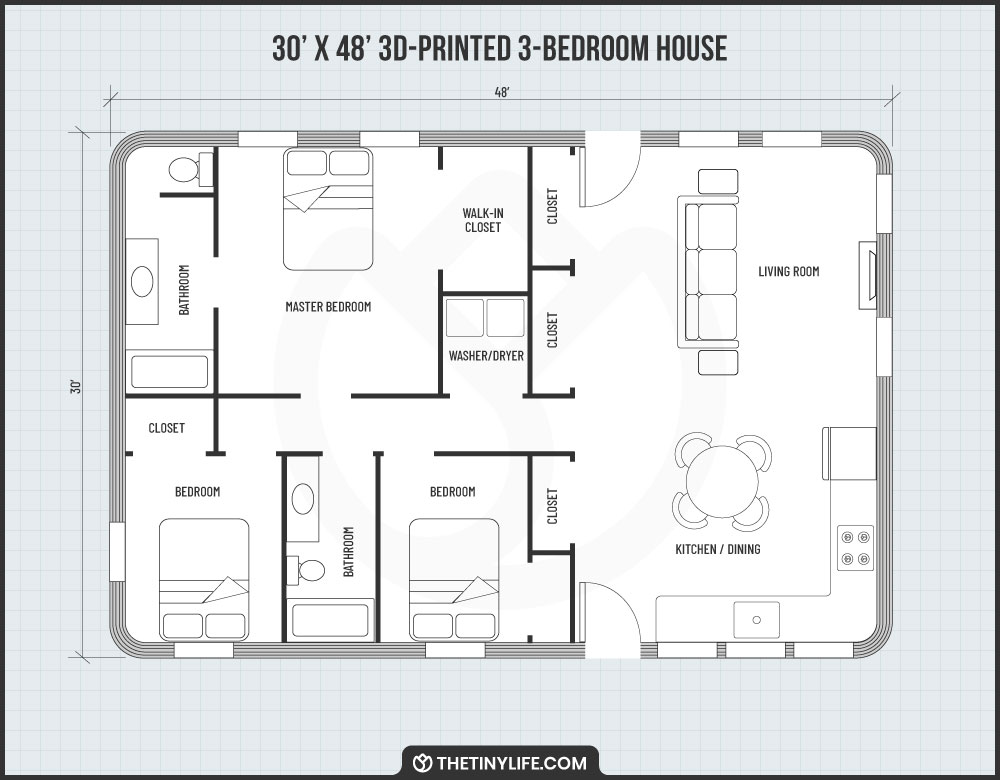

Three-Bedroom 3D Printed House Floorplan

This three-bedroom home has plenty of space for living, lounging, and storage. With an open concept living, dining, and kitchen space, plus lots of extra closets, this 3D printed house floor plan is perfect for a small family or a couple looking for an at-home office and guest space.

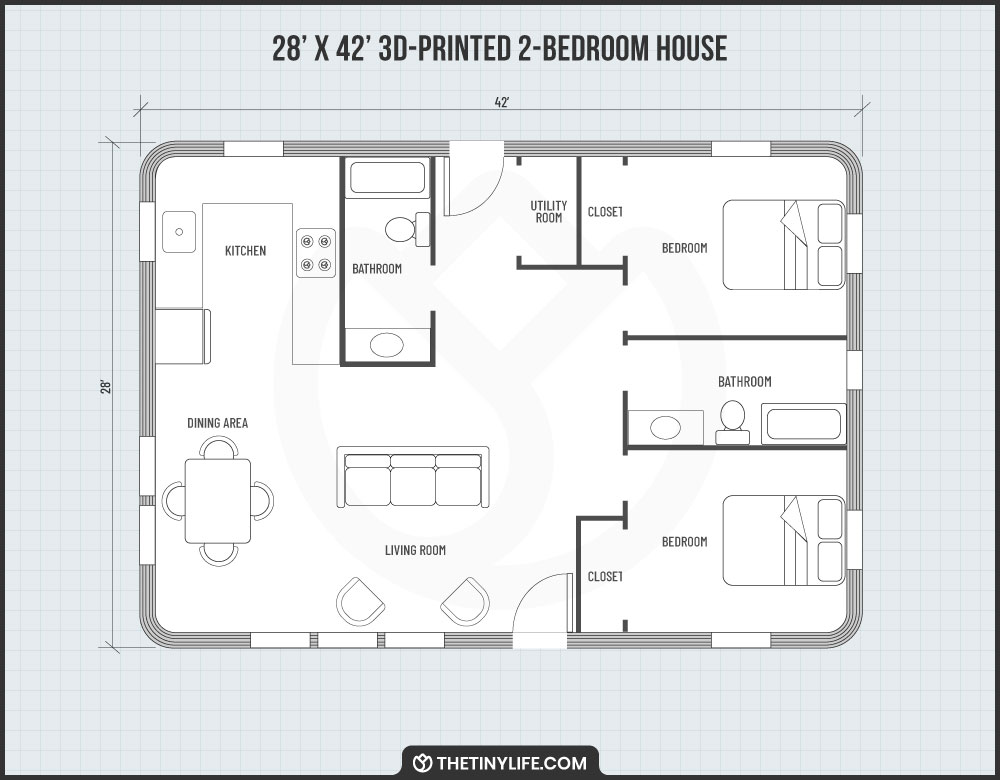

Two-Bedroom 3D Printed House Floorplan

This 3D printed house floorplan creates an ideal space for someone who loves to entertain. With an extra spacious living and dining area with an adjacent kitchen, and just as many bathrooms as bedrooms, this 3D printed house comes together to create a space where memories can be made.

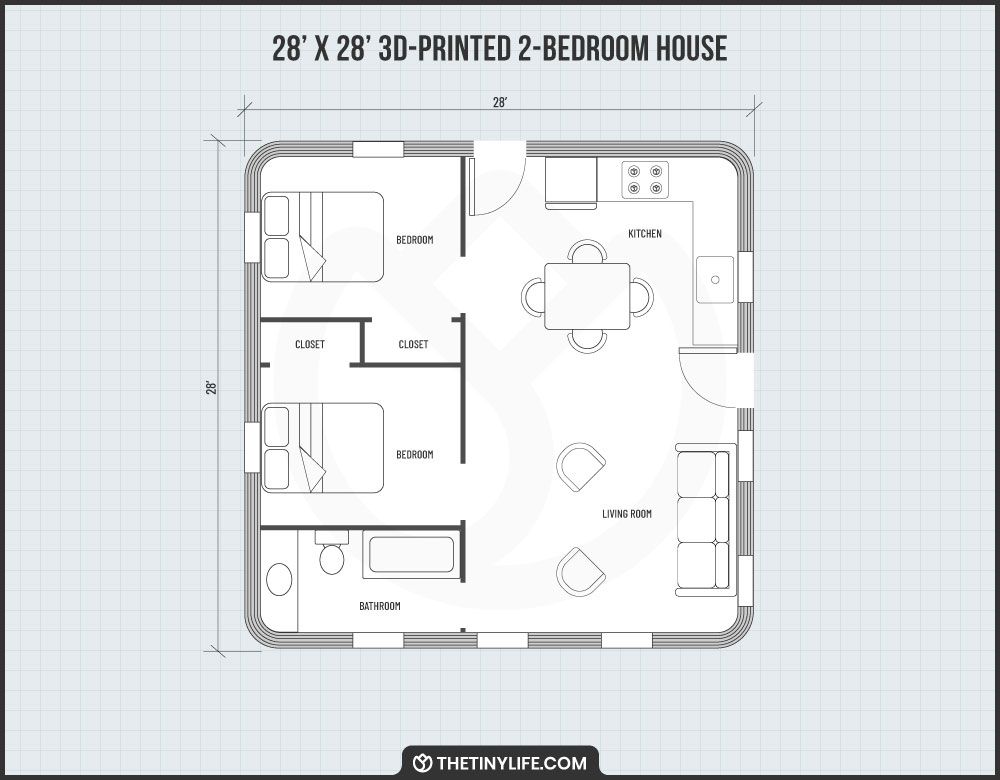

Floorplan For 3D Printed House With Two Bedrooms

This two-bedroom 3D printed house floorplan embraces simplicity in the most straightforward manner. With two quaint bedrooms and a single bathroom, this floorplan is just right for a couple or small family that doesn’t need a lot of extra room but appreciates individual sleeping areas.

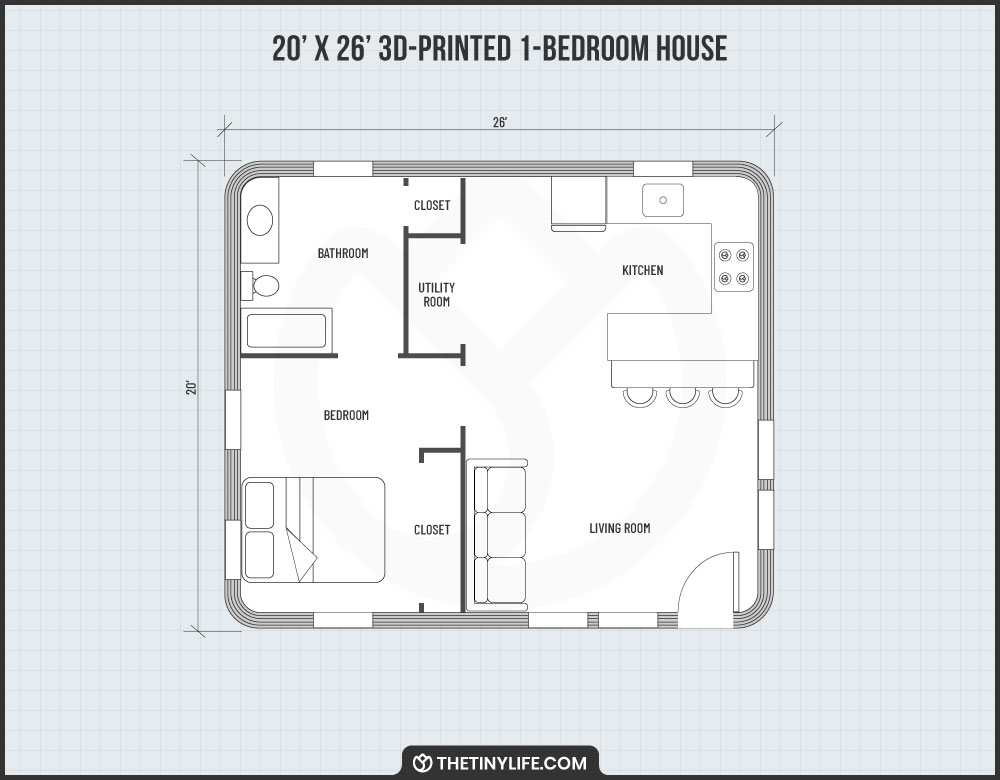

Floorplan For A One-Bedroom 3D Printed House

If one bedroom is all you need, this floorplan will help you create the perfect 3D printed house to fit your simple lifestyle with plenty of legroom. With an extra spacious bedroom and roomy bathroom, this floorplan still includes a nice-sized living room and seated countertop for dining, lounging, or entertaining.

How A 3D Printed Tiny House Is Built

I want to reiterate here the importance of refraining from building a 3D printed tiny home on your own. I tend to tell my friends that DIY building is for anyone, and you don’t have to have a ton of experience to be successful.

However, 3D printing is completely different. With 3D printed housing specifically, it’s not yet possible to DIY this project. While this may become possible in the future, it should be left in the hands of the experts for now.

Tools And Materials List For A 3D House

When it comes to the supplies needed to build a 3D home, some of the materials and tools will be exactly the same tools you’d need to build a house with traditional methods. There are other tools and materials that are unique to building a 3D printed tiny house.

Tools Needed To Build A 3D Tiny House

- Industrial-grade concrete printer

- Leveling slope

- Tape measure

- String line

- Crowbar

- Hammer

- Nails

- Cement screws

- Drill

- Drill bits

- Saw

- Electric sander

Material Options For 3D Tiny Houses

- Concrete

- Mortar

- Plastic or recycled plastic

- Mud

- Rice waste

- Sand

- Metal

- Stone

- Soil or dirt

1 Grade The Land

As with any building project, the first step to building a 3D house is to grade and level the land. Investing in a north-facing plot with high-quality soil will be your best bet for a strong and sturdy build.

2 Build The Framework And Scaffolding

Rails should be placed equidistant from each other so the concrete layers can wrap evenly in between them. The scaffolding will serve as the guideposts to show the printer where to go as it pours the concrete layers.

3 Set Up The 3D Printer

After they’re connected, both the printer and printer head are calibrated to prepare them for action.

4 Print The 3D Tiny House

After the material extrusion is complete, a concrete dryer is attached to the industrial-grade printer that allows the concrete to solidify almost immediately so that another layer of material can be added to the build.

5 Finish The Remaining Elements Of The 3D Printed Home

However, there may come a day where the robots can build all of this for us as well!

Are 3D Printed Houses The Future?

Overall, 3D printing housing isn’t fully ready for DIYers yet, but it’s getting there. Given some time and foreseen technological advancements, 3D printed houses are moving in an exciting direction.

Your Turn!

- Why does the 3D printing building method appeal to you?

- Do you think 3D printing housing changes the future of construction?

HI,

NO thank you, not interested

Will stick to the plan and style I prefer.

Thanks though

As one who teaches energy efficiency in homes, having mass exterior walls is a real no-no as it will be cold in the winter and hot in the summer requiring huge amount of energy to remain comfortable. Exterior walls need to be heavily insulated, preferably on the outside of any mass, and these concrete walls simply aren’t doing that yet. Interior walls are where the mass should be located so it can store any energy fed into the interior with your $$ or thru solar energy input from south facing windows in the northern hemisphere.

I can see how this technology could help with the need for affordable homes in mild climates.

Do you 3d print houses in Pennsylvania? If so what is the lead time for getting one printed? If not do you know of any companies that do?